Produzione meccanica

produzione di parti in metallo o assemblaggi

-

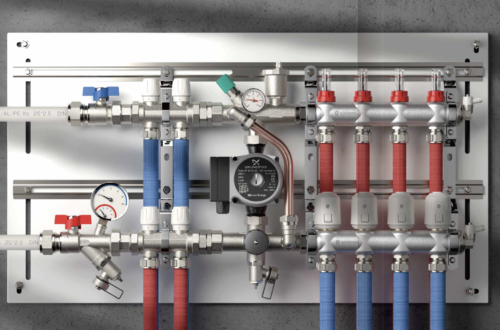

ISPEZIONI PRODOTTI HVAC, E PRODOTTI IN METALLO DALAVORAZIONI CNC

ISPEZIONI E CONTROLLI QUALITA Le nostre “Ispezioni” di controllo qualità sono divise in 3 metodi di intervento. A) Passivo, B) Riflessivo, C) Attivo. Le metodologie sono definite con l’applicazione di interventi, concordati con il cliente ma da sostanzialmente diversi punti di vista. Definizioni degli interventi. PASSIVO Il cliente fornisce schede tecniche relative ai prodotti da ispezionare, vengono effettuati controlli e vengono emessi rapporti correlati. Le ispezioni di solito includono parte o tutte le liste descritte qui: 1- Controllo della produzione, delle materie prime e dei componenti 2 Controllo durante la produzione, sulle linee di produzione 3- Ispezione pre-spedizione, merci confezionate in magazzino 4- Controllo del carico del contenitore, quantità e qualità del carico 5- Monitoraggio della produzione e raccolta di dati di ispezione del personale del fornitore. B) – RIFLETTIVO Il cliente fornisce schede tecniche e rapporti sui problemi riscontrati in precedenza, vengono effettuati controlli sulla linea di produzione del fornitore, (precedente elenco dal 1 al 5) che vengono riflessi al cliente che chiede al fornitore di intervenire con gli aggiustamenti necessari. Le immagini rappresentano lo standard consegnato, non campioni brillanti. Definizioni degli interventi. C) – ATTIVO Con il cliente, valutiamo gli elementi che compongono le caratteristiche del prodotto da…

-

LA QUALITA DEI PRODOTTI MADE IN CHINA MECCANICI LAVORATI

The quality of Made in China Mechanical components is generally under-estimated. Chinese mechanical components manufacturing is the larger player in the world, but there are problems with the quality. China’s production of industrial products far exceeds its domestic consumption and exports. For example, China produced almost 50% more cars last month than Europe did combine. That means that China made about three times more automobiles last month (about 19 million vehicles) than the rest of the world put together(12.7 million units). China’s economy has grown rapidly since 2000 and the country currently accounts for 20 percent of global automobile sales. But, despite having doubled annual economic output in recent ten years, Chinese auto companies’ profitability remains low due to a dearth of advanced technology and skills. Made in China is becoming synonymous with cheapness due to the lower wages offered in comparison with developed countries. Therefore some manufacturers are looking away from labor-intensive production processes and instead focusing on design and assembly methods that require fewer workers and therefore cheaper production costs. (automation) Because of the demand for manufacturing products that are environmentally friendly and safe to consume, there is an opportunity for consumers to enjoy products produced by developing…

-

Scouting mechanical manufacturers in China

Scouting Mechanical Manufacturers in China can be a daunting task, but with the right tools and strategies, it can be an extremely profitable endeavor. Scouting a Chinese mechanical manufacturer can be a helpful step in producing the correct product with. It is important to ask a variety of questions when scouting a factory and to consider a number of factors when selecting a company.

-

How to find suppliers in China

Finding the right supplier in China can be challenging. It’s important to identify where suppliers are located, select the right contact, and check their level of experience. Consider visiting their production centers in person to check the quality of products. If unable to go in person, consider contacting an agency to help find a suitable supplier. By following these steps and taking advantage of available resources, you can successfully find a reliable supplier that meets your needs.

-

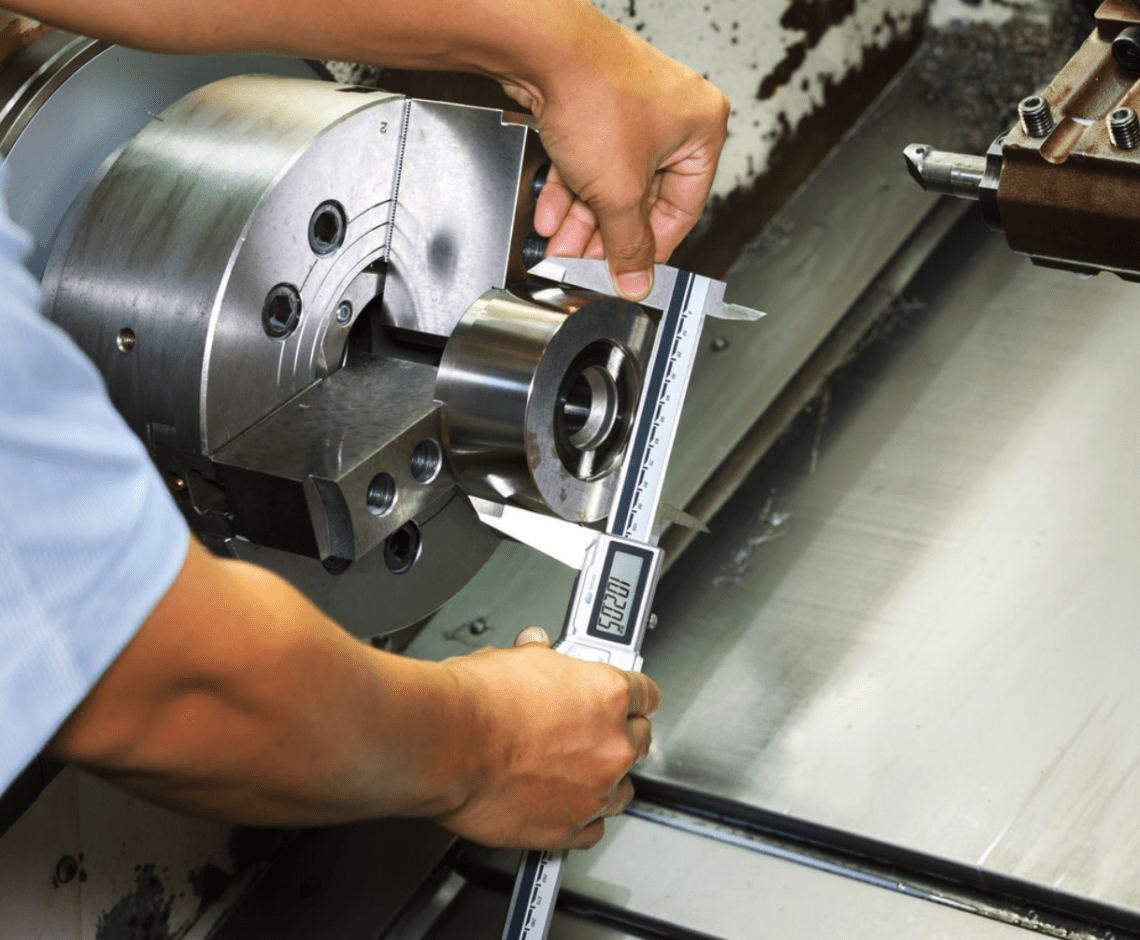

Unlocking Precision: China’s Exemplary CNC Machining Workshops for Mechanical Metal Parts

China's CNC machining workshops have transformed precision manufacturing across automotive, hydraulic, engineering, and consumer goods sectors. With expertise in producing large-sized die-cast gray iron components, precision-casting stainless steel, aluminum, and forged brass, they offer unrivaled accuracy. Cutting-edge precision lathes and multi-spindle lathe machines enable high-volume production of small components. These workshops prioritize flawless execution, adhering to customer quality plans. Their advanced technology fabricates intricate parts, meeting diverse manufacturing requirements. Setting new benchmarks, they provide cost-effective solutions for automotive and industrial applications, ensuring stringent standards for every die-cast component. Versatile operations deliver exceptional results across various materials. Through stringent quality control, they achieve rapid turnaround times in mass production. China's CNC machining workshops embody precision, reliability, and large-scale production capabilities, driving innovation and continuous improvement.